EMF Safety

Working with Magnetic Fields In NDT

Introduction to occupational EMF safety

The International Commission on Non-Ionizing Radiation Protection (ICNIRP) was founded in 1992 – A global body of experts specialized in non-ionizing radiation protection which was assembled to issue guidance on EMF safety. ICNIRP consider the risks posed by low frequency non-ionising radiation like magnetic fields used in NDT.

Since then derivatives of ICNIRP guidelines have been then adopted by different nations (and unions) and written into law through enforceable health and safety directives. Not all the directives are the same - Some use slightly different methodologies or limits. However irrespective of this, many work place directives can be traced back to 3 publications:

- European Directive 1999/519/EC

- ICNIRP 2009 Guidelines ‘on Limits of Exposure to Static Magnetic Fields’

- ICNIRP 2010 Guidelines ‘For Limiting Exposure to Time-Varying Electric and Magnetic Fields (1Hz – 100kHz)

Within the UK - The Control of Electromagnetic Fields at Work Regulations (CEMFAW) 2016

With the UK’s decision to leave the EU The Control of Electromagnetic Fields at Work Regulations (CEMFAW) 2016 came into effect on the 1st of July 2016. This directive is intended to supplement Health and Safety at Work etc. Act 1974 to limit low frequency non-ionising radiation exposure to those in a work place.

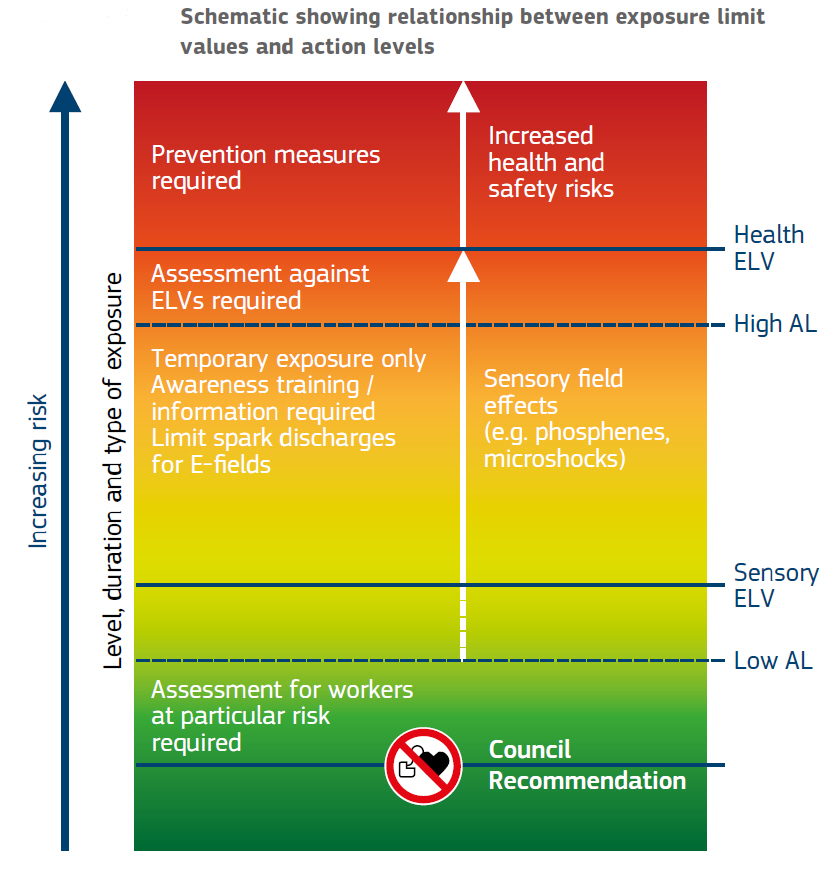

CEMFAW Regulation 2016 describe Actions Levels (ALs), named because if exceeded further action is necessary; to either reduce exposure or establish compliance with a second tier of values called Exposure Limit Values (ELVs).

Limitation on exposure to electromagnetic fields

An employer must ensure that employees are not exposed to electromagnetic field levels in excess of the ELVs described in CEMFAW Regulation 2016.

Exposure may exceed the sensory effect ELVs during work activities in respect of which the employer has taken the applicable safety measures set out in the directive schedules.

However exposure must not exceed the health ELVs to protect personnel against established adverse health effects associated with magnetic fields

Where can I read the UK EMF directive?

Within the EU - European Directive 2013/35/EU

As of the 1st July 2016 the European Directive 2013/35/EU came into effect which outlines the minimum health and safety requirements regarding the exposure of workers to the risks arising from electromagnetic fields (EMF) and is legally enforceable within all EU member states.

What does this mean practically?

Equipment generating electromagnetic fields should be risk assessed and employers must take necessary actions to ensure the risks arising from EMF at the workplace are eliminated or reduced to a minimum.

What are the risks?

While there is presently no conclusive evidence supporting any long term health impacts from low frequency EMF exposure, the directive lists a number of short term health and safety concerns.

These include:

- Localised tissue heating

- Muscle stimulation

- Vertigo

- Phosphenes

- Interference with medical equipment

- Projectile risk

- Fire and explosive risk

Magnetic Field Survey Service

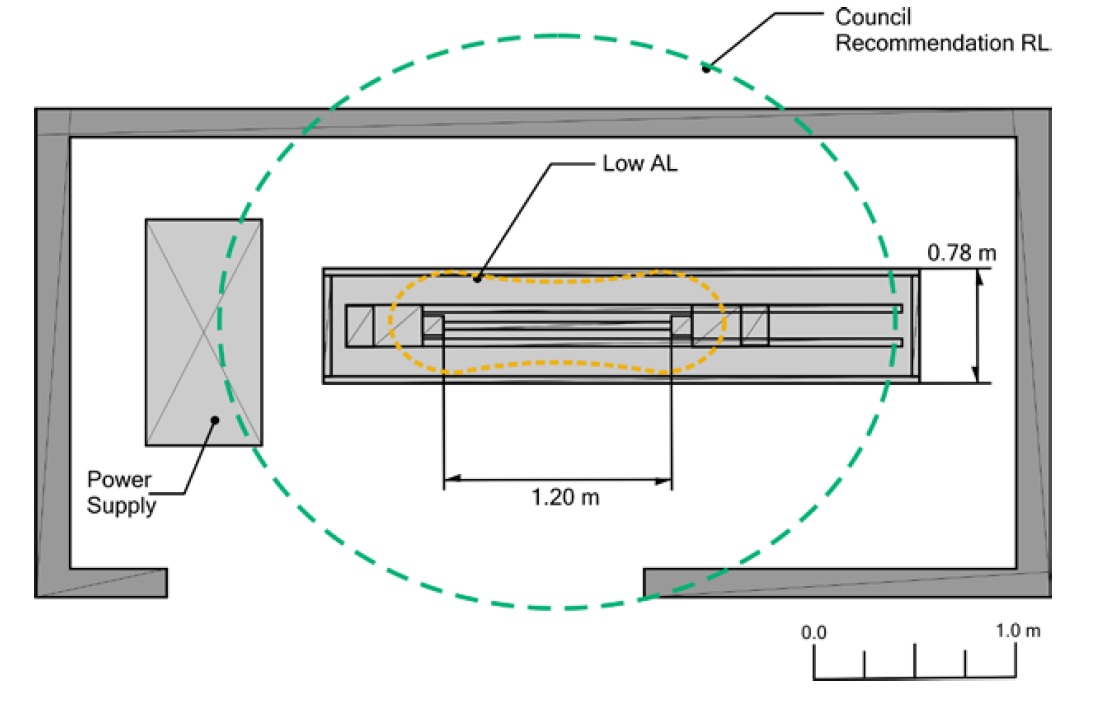

Johnson & Allen make risk assessment easy - We now offer an in-house magnetic field survey service for any location in the UK.

Our professional engineers perform a full risk assessment for equipment (or premises) by taking a number of field measurements using equipment specially designed for determining compliance with the relevant directives.

Johnson & Allen will then produce a full report including the results, a conclusion and list a number of recommendations to pragmatically reduce EMF exposure and give employers and operators peace of mind.

What equipment produces EMF?

In theory any piece of electrical equipment or magnet.

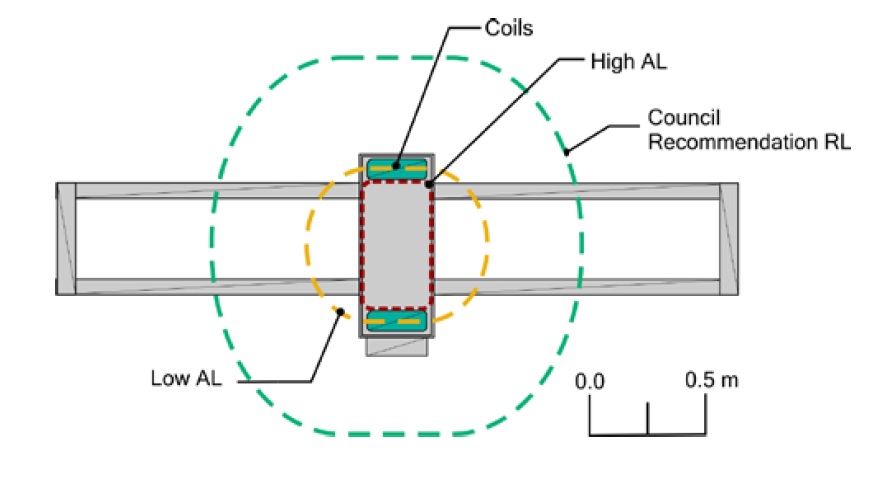

Of course in reality most general electrical products do not produce EMF emissions any where near the action levels listed in the directive. However MPI necessitates the use of strong magnetic fields to find defects.

Thus attention should be given to equipment such as:

- MPI Bench Units

- Power Packs

- Demagnetisers

- Yokes

- Permanent Magnets

- Bespoke Units

What else is Johnson & Allen doing?

While Johnson & Allen makes every effort to provide accurate information for our standard products the nature of MPI and engineering in general creates the need to risk assess in-situ.

Employers should consider:

- How MPI equipment is used

- Exposure time to EMF and shift patterns

- Two or more pieces of equipment in proximity may behave differently

- Through-traffic near to inspection areas

- The impact of EMF on the other side of walls or partitions

- Equipment performance may change over time

Johnson & Allen will continue to update their product literature but we suggest customers with concerns or unanswered questions email our Sheffield head office at:

info@johnsonandallen.co.uk